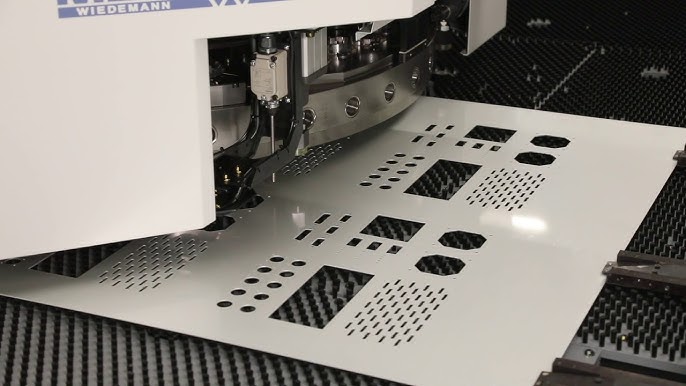

When it comes to sheet metal fabrication, nothing speaks louder than precision.More than metal fabrication, RAAMPS Industries delivers precision solutions that shape the future of performance. If you’re still relying on old-school punching methods, it’s time to discover why our CNC Punching Services are a game-changer.

Here are the top 5 advantages of CNC Punching that are helping industries across the board—from automotive to aerospace—elevate their standards.

- Precision You Can Count On

With CNC Punching, every cut, shape, and hole is made with computer-guided accuracy. This ensures your components fit perfectly every time—no manual errors, no rework. That’s the kind of reliability we deliver at RAAMPS.

- Faster Turnaround Times

Speed matters in today’s competitive market. Traditional punching is slow and labor-intensive. Our **CNC Punching Services** automate the process, reducing production time and helping you meet deadlines without compromising on quality.

- Cost-Effective at Every Scale

Whether it’s a prototype or a large production run, CNC punching adapts effortlessly. Reduced waste, minimized errors, and optimized efficiency mean lower costs for you. And who doesn’t love high performance at a better price?

- Complex Designs Made Simple

Got intricate patterns or unconventional shapes? No problem. CNC Punching allows for advanced customization without the limits of traditional tools. At RAAMPS, your imagination meets our precision engineering.

- Consistency You Can Trust

Every product. Every batch. Every time. CNC Punching ensures uniformity across all components, which is crucial for industries like electronics, aerospace, and automotive where perfection isn’t optional—it’s essential.

Why Settle for Less When RAAMPS Offers More?

From CNC Laser Cutting to advanced CNC Punching Services, we offer end-to-end solutions tailored to your industry’s needs. Whether you’re in electronics, automotive, or industrial manufacturing, our mission is simple: to deliver high-precision components that elevate your brand.

Visit raampsindustries.com today and experience cutting-edge CNC Punching that redefines what’s possible.

Ready to Leave Traditional Methods Behind?

With RAAMPS Industries, you don’t just get parts—you get performance. “Discover the power of precision. Partner with RAAMPS Industries and transform the way you manufacture.

Let’s build something remarkable together.