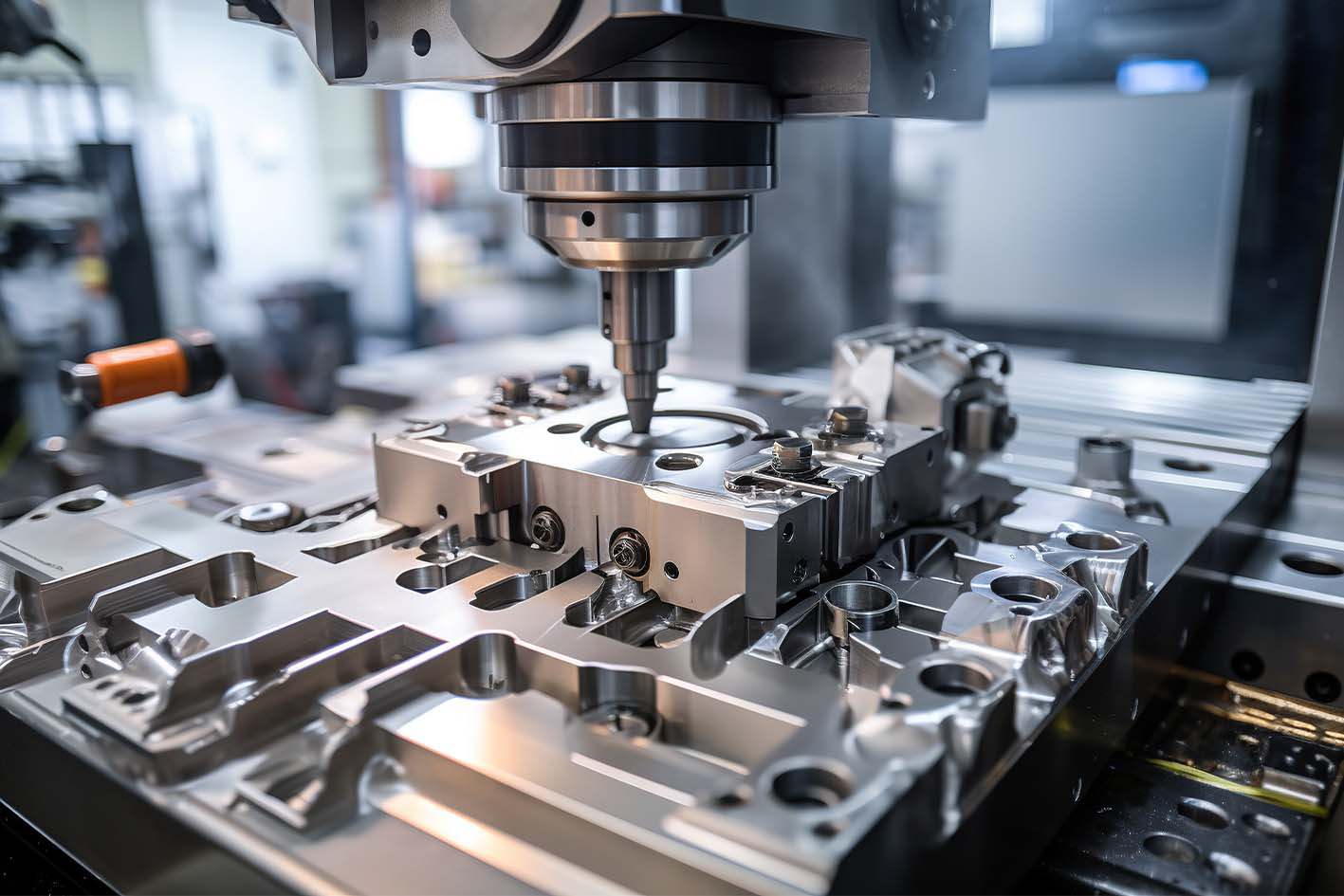

CNC punching represents one of modern manufacturing’s most versatile and precise metal fabrication techniques. This computer-controlled process uses specialized tooling to create holes, forms, and contours in sheet metal with remarkable accuracy and repeatability.

At its core, CNC punching utilizes a punch-and-die mechanism. The punch drives through the metal sheet into a die below, creating perfect holes or forms. What makes this process revolutionary is the computer numerical control (CNC) system that guides operations with programmed precision.

Unlike manual punching methods, CNC punching offers significant advantages that transform manufacturing efficiency. The computer-controlled punch head can rotate, allowing for various shapes and patterns from a single toolset. This versatility enables manufacturers to create complex designs without manual intervention.

At its core, CNC punching utilizes a punch-and-die mechanism. The punch drives through the metal sheet into a die below, creating perfect holes or forms. What makes this process revolutionary is the computer numerical control (CNC) system that guides operations with programmed precision.

Unlike manual punching methods, CNC punching offers significant advantages that transform manufacturing efficiency. The computer-controlled punch head can rotate, allowing for various shapes and patterns from a single toolset. This versatility enables manufacturers to create complex designs without manual intervention.

Applications of Sheet Metal Laser Cutting

Beyond simple hole creation, advanced CNC punching enables specialized forming operations including:

- Countersinking

- Embossing

- Louvering

- Thread forming

Industry leaders like Raamps Industries continue pushing the boundaries of what’s possible with CNC punching. By integrating automated loading systems and sophisticated software solutions, they’ve transformed this technology into a cornerstone of modern metal fabrication processes.

For manufacturers seeking precision, efficiency, and reliability in sheet metal fabrication, CNC punching represents an essential technology that continues to evolve through innovation and expertise.