In today’s competitive manufacturing world, choosing the right cutting method can make or break your project. Every element counts—and at RAAMPS Industries, we make sure nothing is overlooked. That’s why our Laser Cutting Services are tailored for precision, performance, and production speed. But how does laser cutting compare to waterjet cutting—and which is the best fit for your next job?

Let’s break it down.

Speed Meets Precision: Why Laser Cutting Stands Out

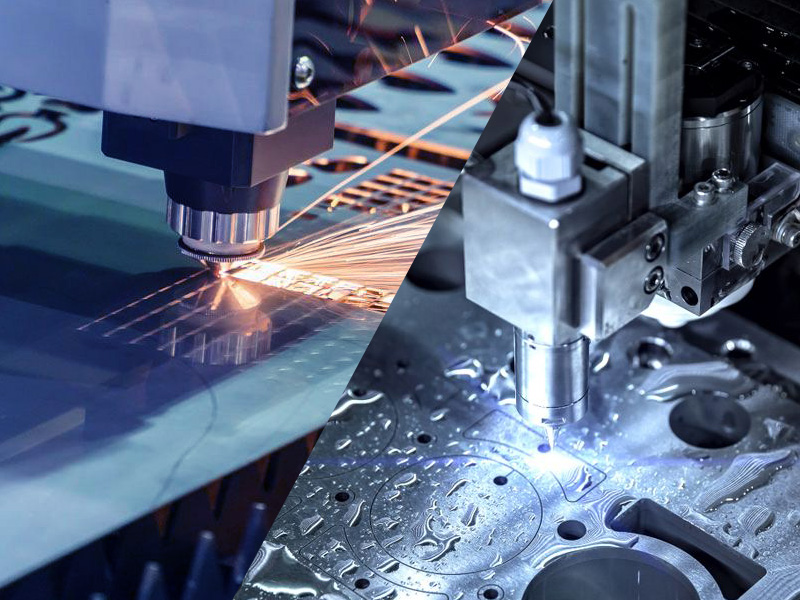

Laser cutting is all about speed and accuracy. Using highly focused light beams, it delivers ultra-clean edges and detailed shapes—perfect for industries like automotive, aerospace, and electronics. At RAAMPS, our advanced Laser Cutting Services allow for intricate designs, minimal waste, and a finish that needs little to no post-processing.

When Waterjet Cutting Works

Waterjet cutting relies on a powerful stream of water, sometimes combined with abrasives, to slice through materials—including those sensitive to heat. It’s great for thicker or non-metallic materials like stone, glass, or composites. However, it’s generally slower than laser cutting and can sometimes lack the refined finish laser systems provide.

Choosing the Right Fit for Your Project

If your project demands high-speed, high-precision cuts on sheet metal or thin materials with tight tolerances, Laser Cutting Services from RAAMPS Industries are your go-to solution. On the other hand, if you’re working with diverse, thicker materials and don’t mind a longer turnaround, waterjet may serve your needs.

Why RAAMPS Industries?

RAAMPS is more than a service provider—we’re your partner in delivering tailored, precision-engineered outcomes. From prototyping to full-scale production, our team brings decades of experience, advanced equipment, and a client-first mindset to every project.

Ready to Cut with Confidence?

Choose the smart way forward. Let RAAMPS Industries guide your next project with precision, speed, and reliability through our industry-leading Laser Cutting Services.

Precision Engineered. Performance Delivered.

Let’s shape your success—starting now.