Our Manufacturing Expertise

At RAAMPS, we specialize in creating unique, custom-made components with exceptional precision and reliability. Our ability to deliver high-quality, accurate parts on time, whether in low or high volumes, sets us apart from the competition.

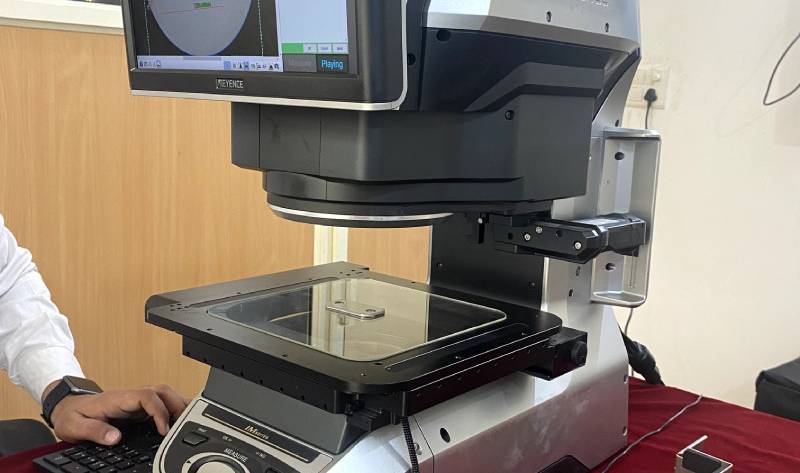

Our advanced precision tools, high-volume production capabilities, and automation systems enable us to meet the exacting demands of our clients efficiently. With extensive technical expertise and experience, we develop high-quality prototypes with seamless transitions and no delays.

We design, build, and maintain our tools, ensuring the protection of your investment and bottom line. Additionally, we offer a range of eco-friendly surface treatments, complex assembly, and packaging services.

RAAMPS Group of Companies

Unit I

RAAMPS INDUSTRIES

GREATER NOIDA – UP

Unit II

ACCURATE INDUSTRIES

GREATER NOIDA – UP

Unit III

CLIXROUTE INDUSTRIES PVT. LTD.

GREATER NOIDA – UP

Unit IV

CLIXROUTE INDUSTRIES PVT. LTD.

HARIDWAR – UP

Unit V

ACCURATE PRESSINGS

RAEBARELI – UP

Unit VI

UNDER CONSTRUCTION

GREATER NOIDA -UP

RAAMPS Group is a leader in precision manufacturing, specializing in the development of custom-made components tailored to meet the unique needs of our clients. With state-of-the-art facilities, advanced automation systems, and a commitment to quality, we deliver highly accurate parts on time, whether in low or high volumes. Our technical expertise, coupled with eco-friendly practices and comprehensive services such as surface treatment, complex assembly, and packaging, ensures that we consistently exceed industry standards while protecting our clients’ investments.

Our Infrastructure

|

|

|

|

|

|

| LASER | CNC PUNCHING | CNC BENDING | POWER PRESS | PLASTIC INJECTION MOULDING MACHINE | |

| Capacities | 2KW, 3KW | 20 Ton | 25 Ton, 50 Ton, 150 Ton | 5 ton-200 Ton | 40 ton – 450 Ton |

| Function | Laser Cutting | Punching | Bending | Blanking, Punching, Forming etc | Plastic Injection Moulding Parts |

| Brand | SLTL | AMANDA | Hindustan Hydraulics | SEW, Balaji | Toshiba, JSW Demag |

| Capability | MS upto 20 mm SS upto 12 mm AL upto 8 mm Copper Upto 5 mm Brass upto 8 mm | upto 3 mm (thickness) | 3000mm | Apros. 40 nos. power press fn House Tool Room | 17 nos. M/C ABS, PP, PC, Nylon in house tool Room |