Enhancing Railway Efficiency & Safety with Cutting-Edge Technology

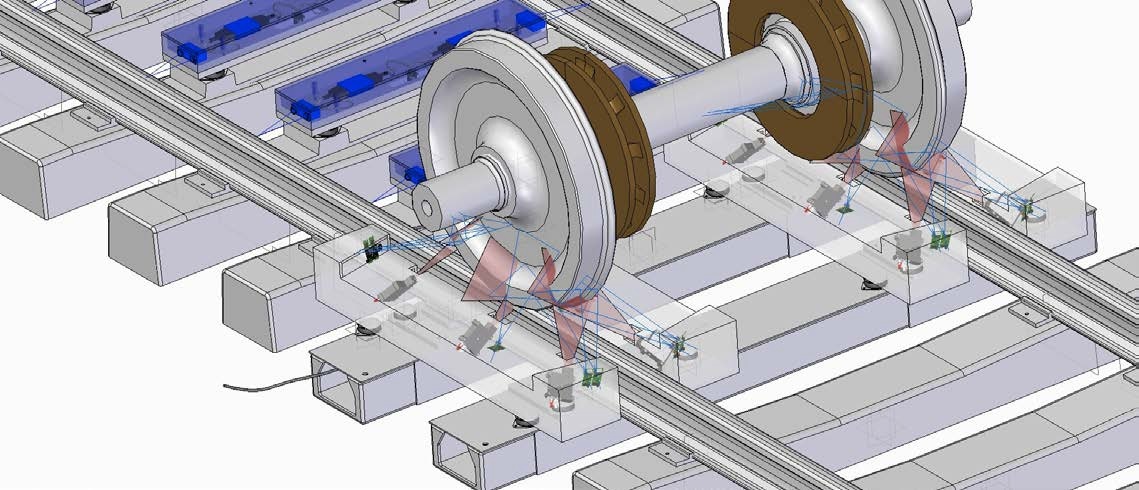

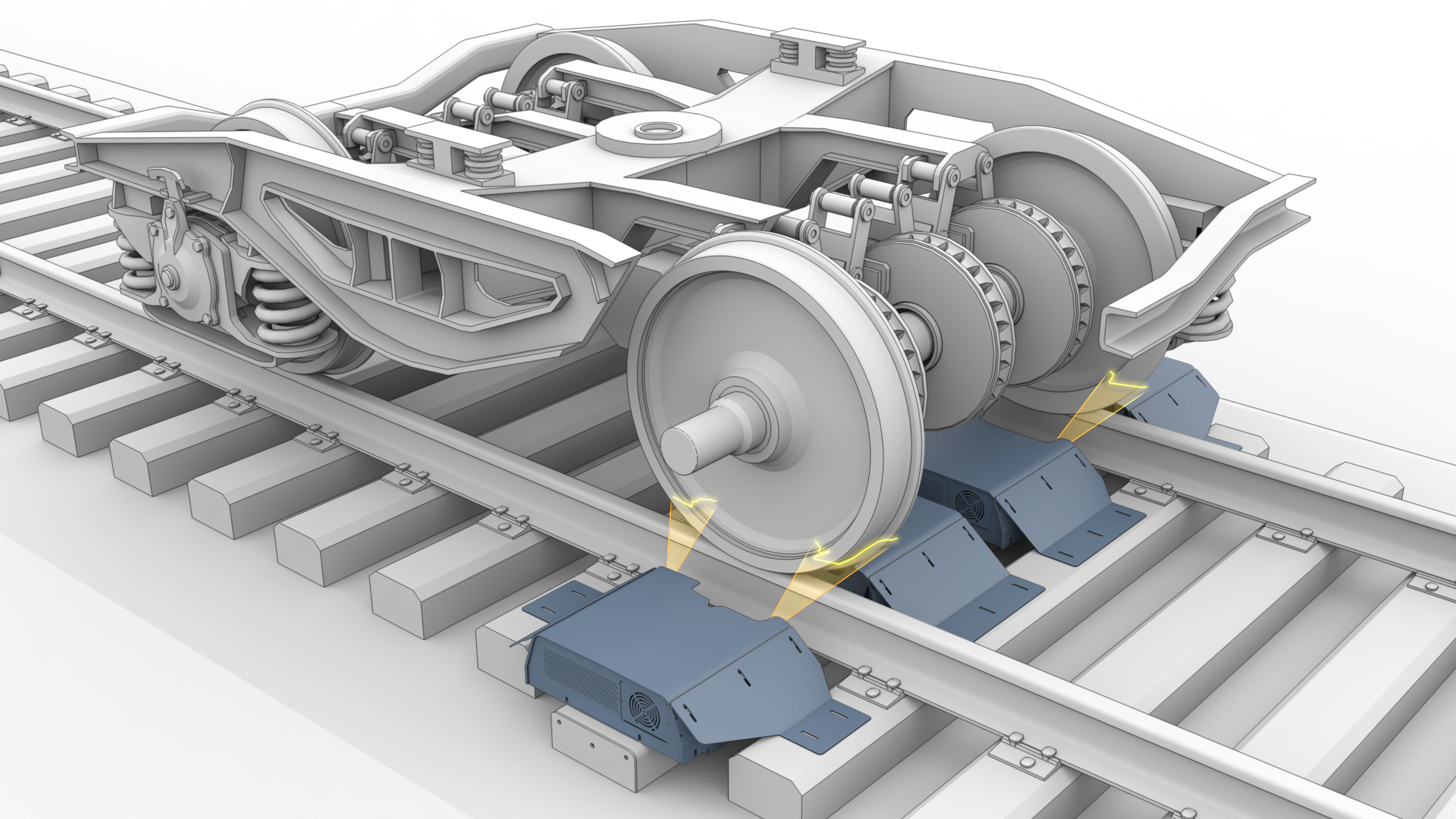

At RAAMPS, we take immense pride in pushing the boundaries of railway technology. Our latest innovation, the Wheel Profile Measurement System (WPMS), is a testament to our commitment to precision engineering and safety in rail transport. Designed to assess the wheel profiles of moving trains, our WPMS ensures optimal wheel health, preventing derailments and reducing track damage caused by excessive wear.

Why Wheel Profile Measurement Matters?

Train wheels are subjected to extreme mechanical stress, influencing not only operational efficiency but also passenger comfort and safety. A worn-out or deformed wheel can lead to severe track damage, increased maintenance costs, and even catastrophic accidents. This is why periodic inspection and monitoring are critical.

Our WPMS offers a non-contact, high-precision measurement solution that enables railway operators to:

✔ Detect early signs of wheel wear before they lead to failures.

✔ Schedule proactive maintenance to enhance operational efficiency.

✔ Minimize rail track damage by identifying potential problem areas.

✔ Prevent derailments through continuous, real-time monitoring.

Advanced Features of Our WPMS

🔹 Real-Time Monitoring – Captures high-speed images and generates precise wheel profile data.

🔹 Surface & Internal Flaw Detection – Ensures wheels are free from critical defects.

🔹 Automated Reporting & Alerts – Helps railway operators take timely preventive action.

🔹 Seamless Integration – Works with existing railway monitoring systems for enhanced efficiency.

At RAAMPS, we are committed to delivering world-class railway safety solutions that meet the highest international standards. Our WPMS is set to revolutionize the way rail operators monitor, maintain, and optimize their fleets.

Proudly delivering state-of-the-art WPMS to our esteemed railway customers!

For more details on how our Wheel Profile Measurement System can enhance your railway operations, get in touch with RAAMPS today!