Perfectly Automated

Always On Point

Lasting Durability

Always On Point

Precision Sheet Metal Components Manufacturers & Plastic Custom Injection Molding

RAAMPS group of companies specializes in manufacturing precision sheet metal components and custom plastic injection molding. With advanced technology and expert craftsmanship, we deliver high-quality, tailored solutions to meet the diverse needs of our clients across various industries.

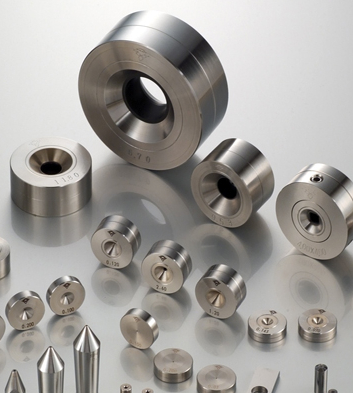

Our services

At RAAMPS Industries, we offer comprehensive sheet metal fabrication services, including CNC punching, laser cutting, precision tooling, stamping, welding, and powder coating. From design to final assembly, we deliver high-quality, customized solutions to meet your specific needs.

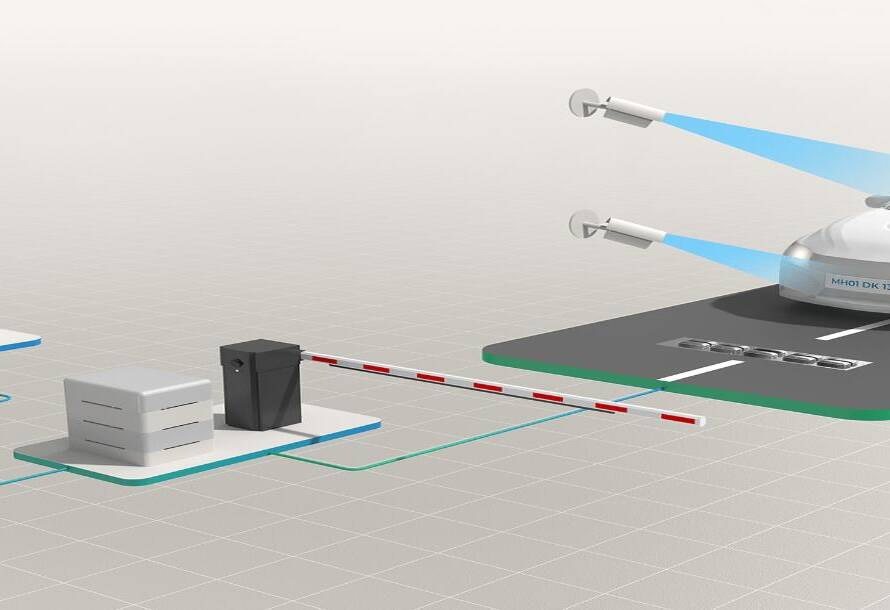

Plastic Custom Injection Molding

We create for clients who value unique quality. Projects can start from a simple sketch!

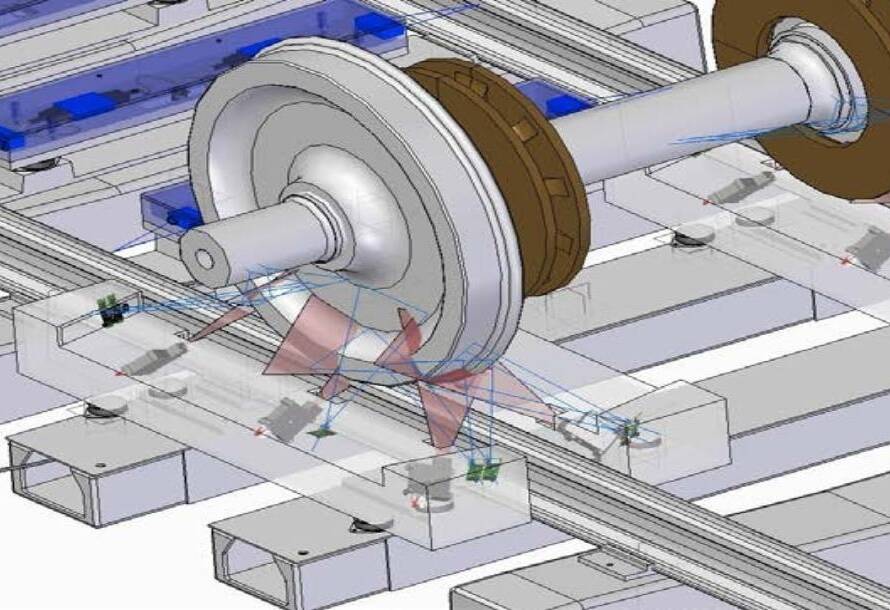

To provide superior sheet metal products that consistently meet or exceed our Customers’ needs and expectations. We strive to consistently deliver the highest quality products by being environmentally responsible, so as we will be recognized as the partner of choice in the industries we serve.

Meet the people behind the scenes

Our leadership team blends experience with forward-thinking strategies, guiding RAAMPS Industries toward continuous growth and excellence.

Core Management Team

Our Core Engagement Team at RAAMPS group of companies is composed of seasoned professionals with deep expertise in sheet metal fabrication and plastic injection molding. Dedicated to excellence, innovation, and customer satisfaction, our team works collaboratively to deliver high-quality solutions tailored to your unique needs. We pride ourselves on building strong relationships and driving success for our clients.

Certificate & Achievements

We are the world class engineering manufacturer providing the highest quality products, services and solutions to our customers.